Double Wall Casings

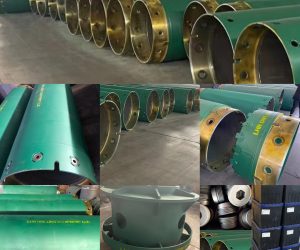

Double-Walled Segmental Casings Temporary Casing

Application

Pile foundation engineering; Full casing construction.

Type

Double-Walled Casing Tube & Single-Walled Casing Tube.

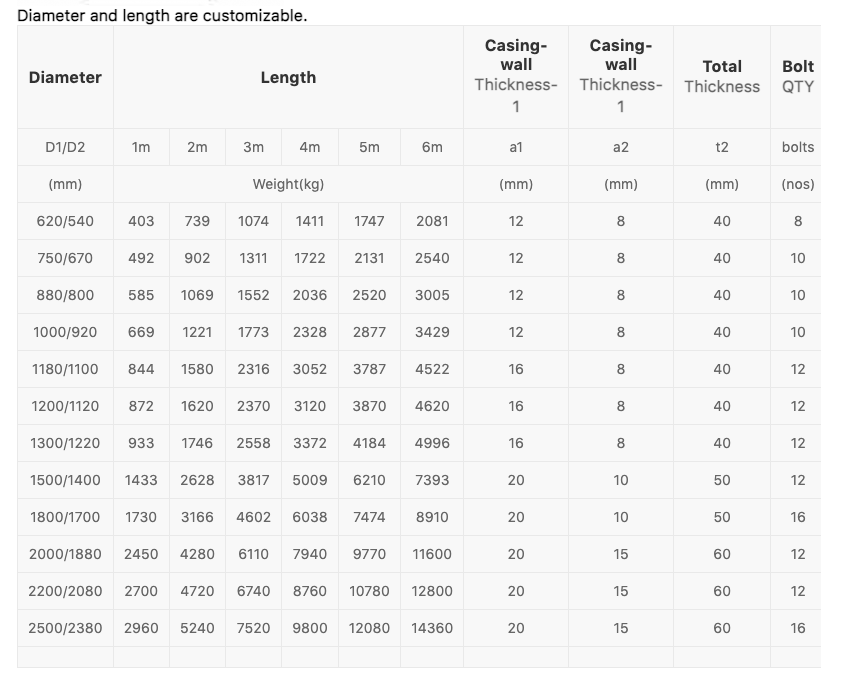

Diameter and length are customizable.

FEATURES

Steel Casings for Cased Bored Piles Construction

LHR Casings are the ideal choice for drilled shaft bored piles construction. It’s effective for many applications in foundation construction and works both as temporary and permanent casing.

LHR Segmental casing was chosen by more than 4000 customers for a number of reasons.

1: Ensuring critical positional and verticality construction tolerances

2: Provide safety protection to an open bore

3: Protect existing and underground structures

How to install the segmental casing?

The casing is installed by a rotary drilling machine or oscillation.

LHR offers a full range of casings, casing joints, casing shoes, and accessories designed to meet the rigorous demands of fully cased pile boring for large diameter and deep foundations in the most difficult soil conditions, including hard rock and other complicated geological environments.

Advance

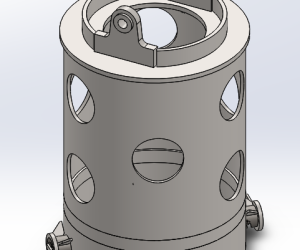

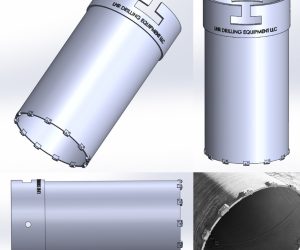

1: Casing tube is different from temporary casing, according to its structure can be divided into single-wall casing and double-wall casing; according to length can be divided into single section 2m, 3m, 4m casing section.

2: Since the casing is equipped with cemented carbide cutting teeth, any soil quality can be adapted, especially when it encounters rock layers, egg layers, isolated layers and so on, so it has a wide range of uses.

3: Construction on soft soil foundation, because the casing will not collapse by first pressing in, so no protective measures are required.

4: In the connection mode of the casing, the button type male / female joint is adopted, and the number of joints varies depending on the casing diameter. This connection method is in line with international standards to ensure the versatility of domestic / international markets.

PARAMETERS

ADVANTAGES

1: No mud discharge, truly green and environmental protection;.

2: Solve the problem of wall protection and drilling of the rotary drilling rig in the complex sand layer, fluid plastic silt layer, backfill layer, pebble layer, etc .;

3: The guiding effect of the casing itself can be used to control the verticality of the pile;

4: There is no effect of mud and sediment caused by mud wall protection on the weakening of the bearing capacity of the bored pile, so that the lateral friction resistance and bearing capacity of the pile are greatly improved compared with other pile types;

5: Avoid the quality problems such as shrinkage, broken piles and concrete segregation that may occur in general cast-in-place piles.

6: The problem of hole wall collapse of the upper unstable section caused by suction and disturbance during drilling is completely avoided.

If you have any inquiry, feel free to contact us, we can help you better! Thank you

- Head Office

- LHR DRILLING EQUIPMENT TRADING L.L.C

- Office 101, DNIR Building, Port Saeed-Deira, Dubai, UAE

- +971 50 424 8594

- info@lhrdrillingequipment.com

- Factory

- LHR FOR STRUCTURAL METAL PARTS MANUFACTURING L.L.C.SP

- Factory # 7760A, Al Jlail, Al Sajja Industrial Area, Sharjah, UAE

- +971 50 424 8594 | +971 54 7115253

- info@lhrdrillingequipment.com

- China Office

- LHR DRILLING EQUIPMENT CO., LTD

- Wuxi, Jiangsu, China

- info@lhrdrillingequipment.com