Desander and Desilter

LHR Desander Sand Separator Slurry Recycling Equipment

Desanders and desilters are solid control equipment with a set of hydrocyclones that separate sand and silt from the drilling fluids in drilling rigs. Desanders are installed on top of the mud tank following the shale shaker and the degasser, but before the desilter. The desander removes the abrasive solids from the drilling fluids which cannot be removed by shakers.

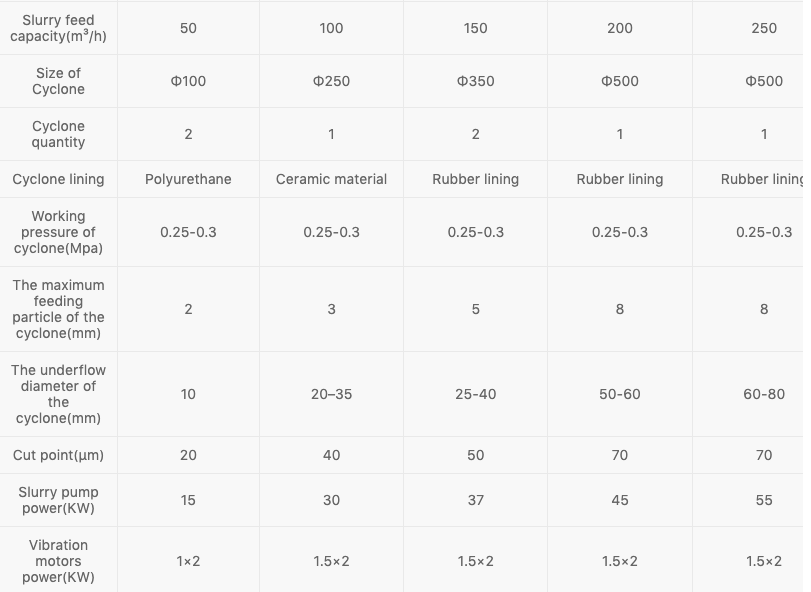

Normally, the solid diameters for desanders to separate would be 45~74μm, and 15~44μm for desilters.

A centrifugal pump is used to pump the drilling fluids from the mud tank into the set of hydrocyclones.

LHR supplies desanders with a capacity ranging from 50-500 m3/h.

FEATURES

What’s Advantage of LHR Slurry & Drilling Fluid Recycling Equipment

Top-quality Betonites is the clay mineral with the strongest swelling properties of all. As a result, the price of Betonites is high accordingly.

Depending on the drilling fluid volume, the drilling fluid is therefore a valuable operating resource. Fortunately, a suitable recycling system could reprocess the slurry for reuse.

By separating the sand which is taken up by the fluid in the process of drilling, the cleaned drilling fluid can be used again in a closed drilling fluid cycle.

In this case, it reduces the mixture time and speeds up the drilling progress, reduces wear of the drilling tools and pumps considerably and decreases the water and Bentonite consumption, which on the whole increases the profitability of a HDD operation or pile foundation project in a sustainable manner.

Screen mesh

The filter system made of PU mesh is characterized by its light weight, long serving life, energy saving, and outstanding anti-corrosion capability.

Floating device

Perfect combination of buoy and foam plate realizes automatic adjustment of slurry amount and fluid between overflow tank and slurry container.

Hydrocyclone

Making good use of hydrocyclone self-separation and deposit working principle as the second important part of filter system to ensure the slurry separation degree within 60 μm.

Controlling system

Electrical controlling system ensures safe and convenient operation as well as triggering alarm signal and self-protection system in emergency.

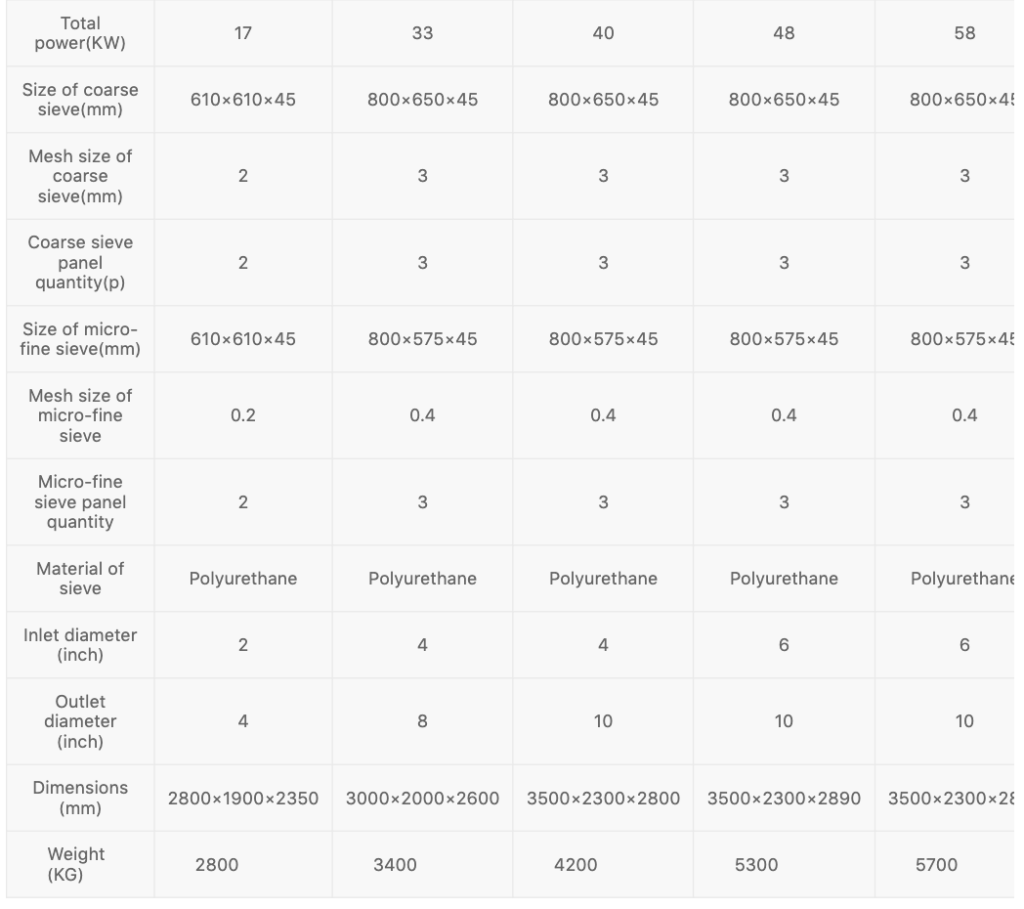

PARAMETERS

ADVANTAGES

1: High mud handling capacity, sand can be removed efficiently.

2: The oscillating screen has many advantages such as easy operation, low trouble rate, convenient installation and maintenance, low operation noise.

3: The cyclone with advanced structural technology can efficiently separate sand from slurry. Moreover, it features in light weight, corrosion and abrasion resisting material, so it can work stably in the worst condition without maintenance.

4: The special designed automatic liquid-level balancing device can not only keep the liquid-level of the slurry reservoir stable, but also realize the reprocessing of mud, so the purification quality can be further enhanced.

If you have any inquiry, feel free to contact us, we can help you better! Thank you

- Head Office

- LHR DRILLING EQUIPMENT TRADING L.L.C

- Office 101, DNIR Building, Port Saeed-Deira, Dubai, UAE

- +971 50 424 8594

- info@lhrdrillingequipment.com

- Factory

- LHR FOR STRUCTURAL METAL PARTS MANUFACTURING L.L.C.SP

- Factory # 7760A, Al Jlail, Al Sajja Industrial Area, Sharjah, UAE

- +971 50 424 8594 | +971 54 7115253

- info@lhrdrillingequipment.com

- China Office

- LHR DRILLING EQUIPMENT CO., LTD

- Wuxi, Jiangsu, China

- info@lhrdrillingequipment.com