LHR Friction Kelly Bars

FRICTION KELLY BARS

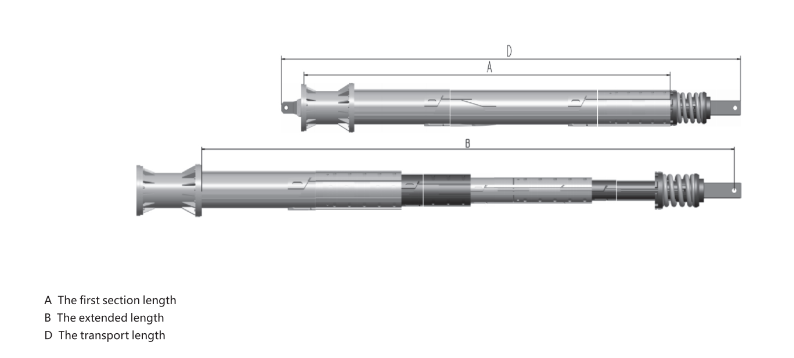

Application:

Friction kelly bars are normally supplied in 4 or 5 telescopic elements, they are mostly used for deep piles of silt, clay and less dense sand and gravel.

Kelly Sections:

Kelly bar 2-5 sections.

Type:

Interlocking/friction/combined kelly bar.

Size:

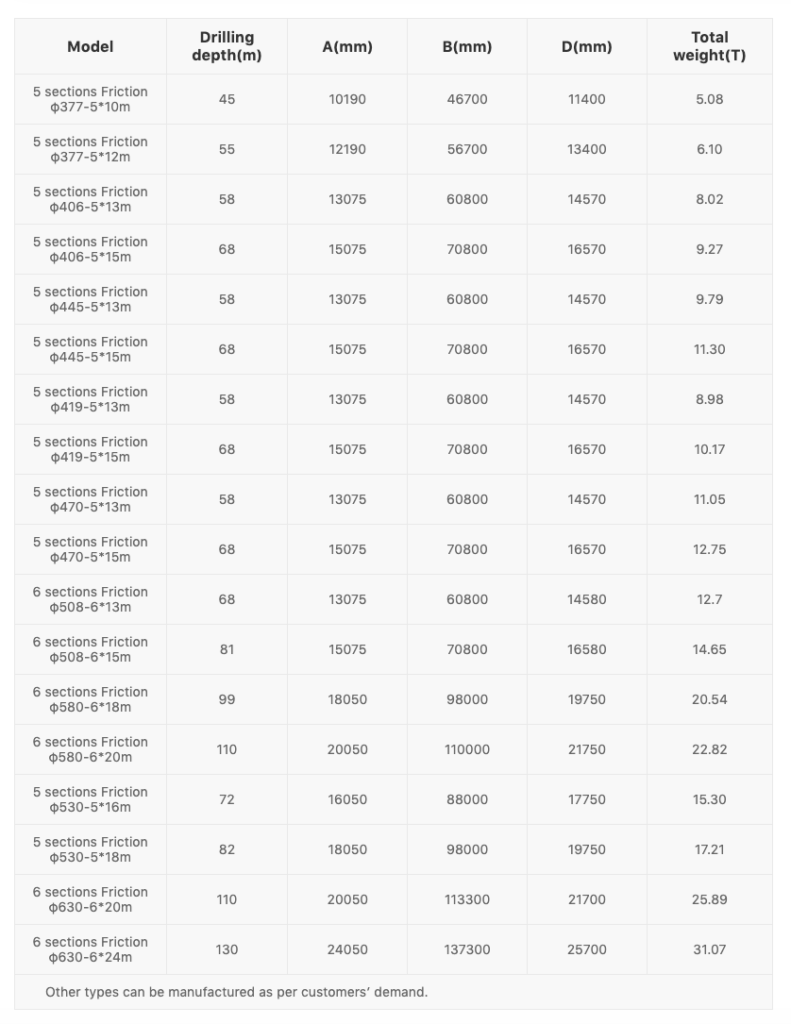

Diameter range from 355mm-630mm.

Warranty:

One year.

FEATURES

Friction Kelly bar is another type of kelly bar, which the external key is composed of 3 or 6 wear -resistant strips without lock recesses. This kelly bar can form pressure force when the kelly bar is rotary. can produce peripheral force and the rotary passing down the pressure force, can produce the friction force. This kelly bar has the advantage of operating sample, drilling deep, but with less pressure transmission.

ADVANTAGES

The most professional R&D and production team

The core R&D, processing and production personnel are all from the leading enterprises of this industry, with more than ten years of experience in the design and manufacture of kelly bars. We have provided tailor-made Kelly bar and technical services for almost all the well-known brand names of rotary drilling rigs both at home and abroad.

Top quality special steel materials

The steel pipe used in the Kelly bar comes from the selected materials made by first-class steel enterprises at home and abroad. The yield strength and service life are more than doubled compared with the general-purpose products, meeting the rigorous requirements in drilling soft soil and various strata.

The cutting-edge manufacturing technology

The core parts of kelly bars, such as square head, driving keys, and locking recesses, are made of imported steel by special heat treatment and surface strengthening treatment, which not only feature high yield strength, wear resistance, impact resistance, strain capacity, welding property and corrosion resistance, but also meet high reliability requirements of kelly bars in the construction of hard rock, large diameter and super deep piles. From the strict control of raw materials to multi-layer and multi-step precise welding, we comply with strict quality standards and monitoring systems in all aspects of kelly bar production to ensure 100% high standard quality. We are also the first kelly bar manufacturer to provide customers with a one-year warranty.

If you have any inquiry, feel free to contact us, we can help you better! Thank you

- Head Office

- LHR DRILLING EQUIPMENT LLC

- Office No, 4101-02, Churchill Tower, Business Bay, Dubai, UAE

- +971 50 424 8594

- info@lhrdrillingequioment.com

- Factory

- LHR AUGER CONVEYOR MIDDLE EAST LLC

- Al Sajja Industrial Area, Sharjah, UAE

- +971 50 424 8594

- info@lhrdrillingequipment.com

- China Office

- LHR DRILLING EQUIPMENT CO., LTD

- info@lhrdrillingequipment.com