Hydraulic Round Pile Breaker

Hydraulic Round Pile Breaker

& Pile Cutting Machine

BRAND

LHR DRILLING EQUIPMENT

MODELS

LHR

WARRENTY

1 Year

APPLICATION

Breaking down the concrete pile header for foundation pile

FEATURES

Effective Concrete Pile Breaker & Pile Cutting Machine

For pile foundation, chopping concrete piles can be challenging, especially with strict site norms. And the traditional manual way is no longer applicable due to its inefficiency and a host of other potential hazards. You will need a revolutionary way to dismantle pile concrete to cut-off level.

LHR Pile Breaker is an efficient, economical, clean and advanced system for cutting concrete outcrops and foundation piles.

The modular design makes the pile breaker extremely easy to crush concrete piles of different diameter at the jobsite. Additionally, each module contains a separate cylinder and brazing rod system. With the help of hydraulic pressure, the oil cylinder drives the brazing rod to squeeze the pile.

Thanks to this way of working, no cracks and damage will be caused to the pile and reinforcement underground. Also, thanks to the independent modular structure, air and noise pollution in construction sites will be reduced significantly.

When it comes to the efficiency of our pile crusher, we have the detailed data to back it up. The traditional way of crushing normally takes one day for one pile. However, the LHR pile breaker is more than 10 times faster than the traditional breaking process due to its automatic process.

Easy To Assemble

The concrete pile breaker is easy to operate and maintain because it does not require special skills. And we will offer comprehensive installation and maintenance instruction. Our instructions include all the information you need to install and operate the pile breaker, ensuring that you can get the most out of them. If necessary, we can also provide video instruction.

Simple and flexible way for Pile Foundation

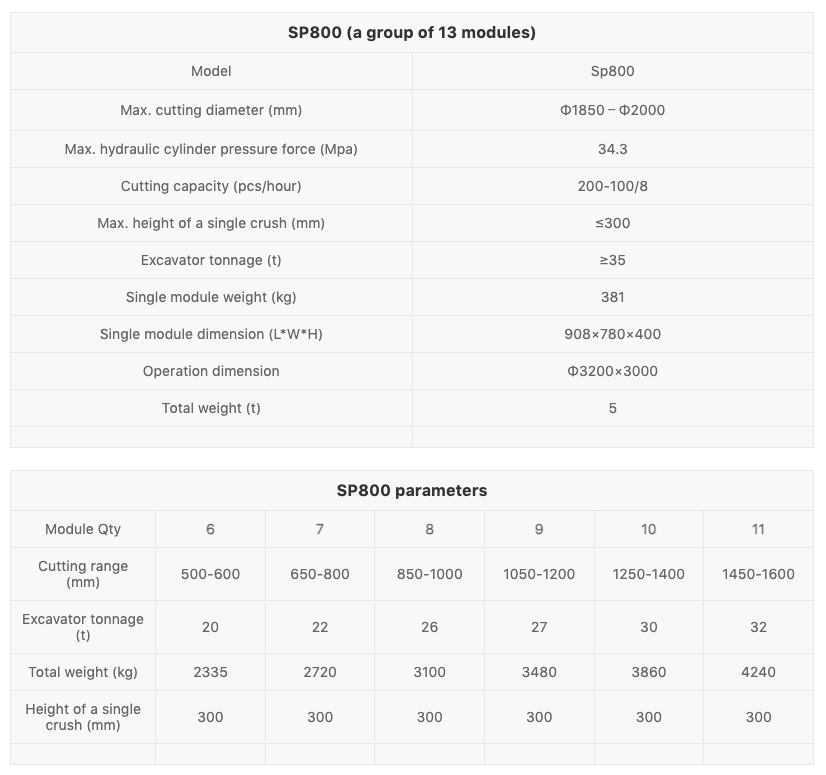

SP800 Convert To A Square Pile Crusher SP800 pile breaker consists of 13 modules. Each module is identical. Different numbers of modules can be assembled to form a pile cutter for different pile diameters. In addition, with 4 adapters (purchase additional), you will get a new square pile breaker which cuts square piles range from 300mm to 500mm.

For Large Concrete Piles up to 2m!

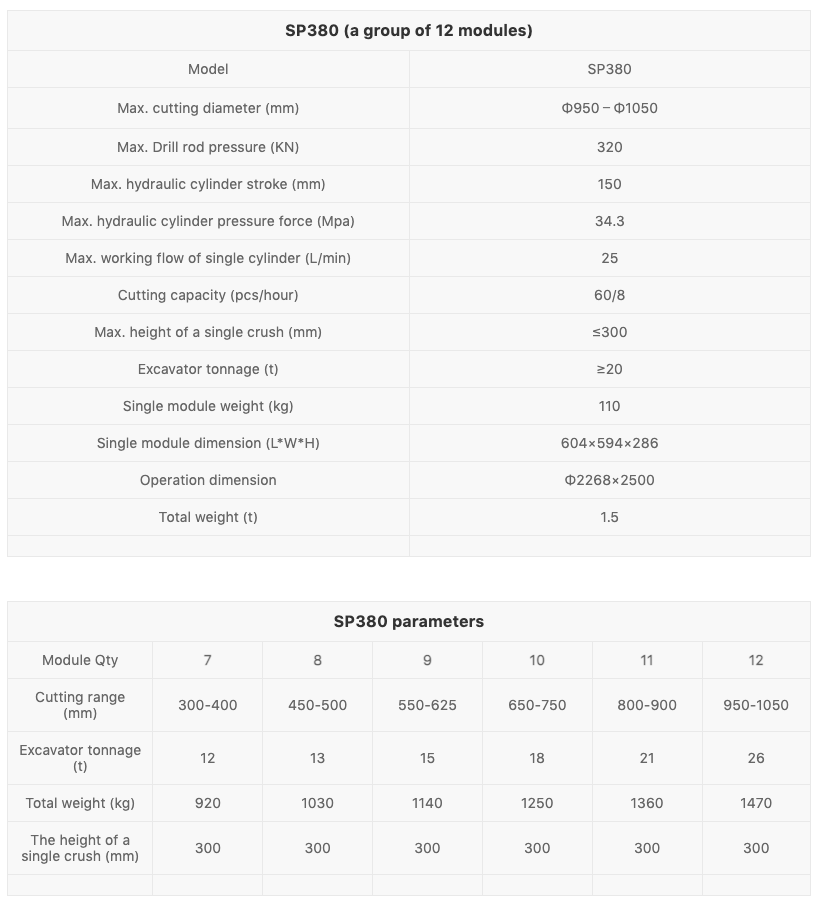

A pile breaking machine which consists of 5 modules could cut piles between 40 to 50cm. Moreover, with 13 modules, it could break piles up to 2m in diameter. The following table shows more details.

PARAMETERS

ADVANTAGES

1: Environmental, low noise and dust.

2: Efficient and Economic, cutting 20-100 piles per day.

3: Stable, no destabilisation of underground piles.

4: Flexible, assemble modules like building blocks to fit piles of different diameters and shapes.

5: Convenient, modules can be disassembled for transport and assembly.

If you have any inquiry, feel free to contact us, we can help you better! Thank you

- Head Office

- LHR DRILLING EQUIPMENT TRADING LLC

- Office No, 4101-02, Churchill Tower, Business Bay, Dubai, UAE

- +971 50 424 8594

- info@lhrdrillingequioment.com

- Factory

- LHR FOR STRUCTURAL METAL PARTS MANUFACTURING (SPS-LLC)

- Workshop-6, Al Jurf Industrial Area 2, Ajman, UAE

- +971 50 424 8594 | +971 54 7115253

- info@lhrdrillingequipment.com

- China Office

- LHR DRILLING EQUIPMENT CO., LTD

- Wuxi, Jiangsu, China

- info@lhrdrillingequipment.com